The answer is simple. Cardboard is one of the most popular and demanded packaging materials. It has many properties that make it the best mode of packaging solutions. Therefore, rising demand brought in increasing revenue. However, the low production cost of these corrugated cardboard boxes played a significant role in ensuring that the profits of the companies skyrocketed. This factor is what allows the cardboard business to be such a profitable venture for manufacturers.

Today, when you look around you, you will see at least one cardboard packaging lying around. Anything that you can see has probably been packaging into these boxes. What makes them so practical and useful?

Post Contents

Why do we even use cardboard?

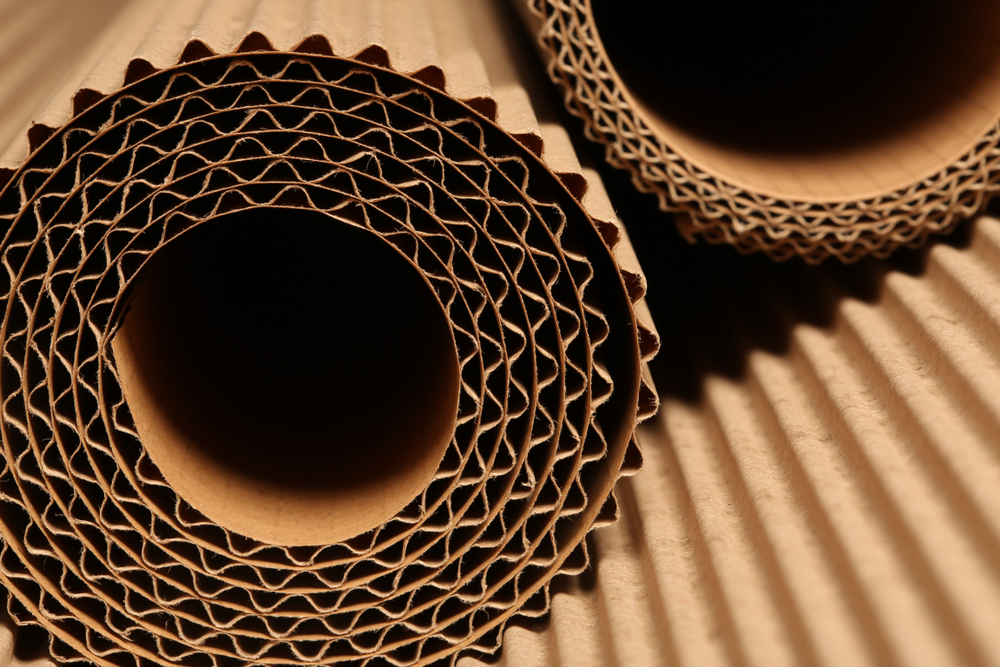

Imagine a material that you can fold, cut, mould, and stick into any shape and size possible. Then you can paint, print, design, and write anything on that material. Not only that, the package prevents any outside environmental element gets into contact with the items inside it. It is lightweight, easy to carry, easy to assemble and easy to customize. It does not require much effort to make and set up. Also, it is a biodegradable and environment-friendly material, which helps you to reduce your carbon footprint. It is robust, durable and can be used to carry all sorts of items.

If you can imagine such a useful and versatile packaging product, then you can see why manufacturers are so eager to use it for their products. Any box made of corrugated cardboard sheets will have these properties.

Since it is so useful and easy to produce, the production costs of cardboard are amazingly low. You can quickly get your hands on this material, through online dealers, or even your local scrapyard. You can get them on wholesale rates, or also produce them yourself. This is one of the main reasons why the product is so popular.

How to reduce costs with cardboard?

You are interested to know about how you can incorporate the use of this material in your manufacturing process, to reduce your production costs? We have made a list of some ways in which you can quickly reduce your packaging costs. Just use corrugated cardboard sheets, and see the significant reduction in your packaging costs.

Buy in bulk:

It is no secret that bulk buying is none of the most effective ways of reducing costs. But what are you going to buy? There are two options. You can buy the boxes in bulk, and use them as such in your production. This is a straightforward and convenient process. You can contact any local producers.

If there are none available, you can quickly look for companies that make boxes on the internet. The second option is much more popular, as it is very convenient and practical. The second method is to bulk buy the cardboard sheets through the same channels. Once you have the leaves, you can easily make them into customized double wall corrugated cardboard boxes according to your brand design.

Compact designs:

One of the best ways to make your cost low is to make simple boxes. There is no need for overly fancy and large plates, which are discarded by the customer. Large boxes are no longer in fashion. Retailers and customers prefer small and convenient to carry boxes. Make sure that you design the tables in such a way that they occupy less space. One benefit of compact boxes is that they use less cardboard, which will help you to save a large sum of money.

You can make more boxes from the same sheet. Secondly, it is more suitable for retailers to display compact boxes on the shelves. This will allow them to show more of your product on the same shelf space, which will be useful for marketing. As for the consumers, they always prefer small and easy to carry boxes. Also, when shipping, you can transport more boxes in the same container, if you can reduce the size of the box. If you can provide that comfort to both of these parties, you can be assured of higher sales. A compact design will save packaging costs and increase revenue, as shown by the records from Amazon and FedEx.

Minimalism:

Most manufacturers are aware of the recent trend of consumers to go for minimalist designs and shapes. It is one of the many ways to reduce costs and attract customers at the same time. Minimalist forms will require you to make functional and straightforward boxes that are efficient and cost-effective — no need to go for fancy lids and handles. Today’s customers will prefer the boxes which are simple and fulfil their roles effectively. Another aspect of minimalism is to reduce the designing of your boxes.

There is a wide variety of designs available that can make the table look as stylish as possible. The great thing about cardboard is that you can easily print on it. Printing is one of the cheapest means of designing on the box. Make sure that you make the text and details as concise and practical as possible, using halftone ink. Great examples of this minimalist design would be the iPhone packaging.

Eco-friendly packaging:

A generally held view is that eco-friendly packaging is expensive. That is a myth. Cardboard is biodegradable and one of the cheapest forms of packaging available in the market. You can reduce the packaging cist by using this material. It is made from organic materials, which are readily available.

It also does not require any sophisticated production techniques or a large labour force. Reduce your money and environmental costs by using corrugated cardboard for crafts. Also, you can reuse the material, which is excellent, as you can buy the same sheets from a scrapyard at wholesale rates and save a lot of money.

Increase efficiency:

the secret to cost-effective production is to use efficient means of production. Make sure that the process you are using to package your items is efficient. Use automation to save time and money. Use inventories to manage warehouse space and shipping schedules. You can invest in research for cheap packaging solutions. Research into cheap packaging is what led to the creation of cardboard.

You can make the production process efficient by using the famous production line process. There are many ways in which you can make sure that the packaging process is as effective as possible. Therefore, we can see how it is essential to reduce costs for any business. And to do so, they need to be efficient in a wide variety of areas. We have provided some excellent and practical ideas to make the packaging costs lower and revenue greater.